to disassemle the clynder head, i loosened the bolts holding the cam shafts. Marked on the holders is either "E" for intake or "I" for exhaust to indicate which side they go. to remove valves, i used a valve compressor.

the first test is a visual inspection for any damage to the compenents. common damage is rusting,cracking warping or carbon build up. i found none and proceeded with the checks.

this picture is off the valves and springs when removed from the cylinder head.measured the components were within specs and were good for further use

Valve Spring Squareness(using set square to measure)

1. 0.508 0.508mm OK

2. 0.483 0.457mm OK

3. 0.076 0.178mm OK

4. 0.483 0.457mm OK

5. 0.508 0.584mm …....................................OK l

6. 0.762 0.711mm OK

7. 0.711 0.711mm OK

80.483 0.457mm OK

Valve spring free length:

(Note: All springs in a set should have a free length within 1.5 mm of each other.)

1. 47mm 47.34 mm OK

2. 47.9mm 47.50mm OK

3. 47.6mm 47.46mm OK

4. 47.5mm 47.44mm OK

5. 47.5mm 47.60mm OK

6. 47.5mm 47.60mm OK

7. 47.5mm 47.55mm OK

8. 47.5mm 47.50mm OK

Valve spring installed height:

1. 39.52mm 39.56mm OK

2. 40mm 39.66mm OK

3. 39.66mm 39.37mm OK

4. 39.3mm 39.56mm OK

5. 40.32mm 39.52mm OK

6. 40.38mm 39.81mm OK

7. 39.81mm 40.94mm OK

8. 39.96mm 40.06mm OK

I check the spring tension or seat pressure which is checked on a valve spring pressure tester at the installed height obtained before. All measures should be in 5kilograms of each other

1. 18kg 17.6Kg OK z

2. 16.7kg 18.2Kg OK z

3. 17.8kg 18.1Kg OK z

4. 19.4kg 17.4Kg OK z

5. 15.6kg 18.1Kg OK z

6. 15.6kg 17.4Kg OK z

7. 17.3kg 14.3Kg OK z

8. 16kg 16.2Kg OK z

the camshaft was measured for taper and ovality and passed specification.

the cam lobes were measured for wear, passed specification for further use

Front | Middle | ||

1 | 2 | 3 | |

Journal Ovality | 26.043mm | 26.043mm 26.043mm | 26.043mm |

Journal Taper | 0 | 0 0 | 0 |

OK ‚ | OK ‚ | OK ‚ | |

Front | Middle | ||

1 | 2 | 3 | |

Journal Ovality | 26.043mm | 26.043mm 26.043mm | 26.043mm |

Journal Taper | 0 | 0 0 | 0 |

OK ‚ | OK ‚ | OK ‚ | |

the results below are for the cam lobes and their lift. the intake and exhaust lobes would have been the same at manufacture but due to wear from usage they change in measurements

- Inlet:- (A)41.03mm - (B)33.0412mm = (Lift)7.988mm

- (A)41.03mm - (B)33.041mm = 7.989mm

Cylinder 1.

- Exhaust:- (A)41.039mm - (B)33.001mm = (Lift)8.038mm

- (A)41.038mm - (B)33.001mm = 8.037mm

- Inlet:- (A)41.03mm - (B)33.043mm = (Lift)7.987mm

- (A)41.04mm - (B)33.043mm = 7.997mm

Cylinder 2.

- Exhaust:- (A)41.039mm - (B)33mm = (Lift)8.039mm

- (A)41.037mm - (B)33mm = 8.037mm

- Inlet:- (A)40.53mm - (B)33.045mm = (Lift)7.485mm

- (A)40.53mm - (B)33.044mm = 7.486mm

Cylinder 3.

- Exhaust:- (A)41.038mm - (B)33mm = (Lift)8.038mm

- (A)41.039mm - (B)33mm = 8.039mm

- Inlet:- (A)40.531mm - (B)33.043mm = (Lift)7.488mm

- 40.53mm - (B)33.044mm = 7.486mm

Cylinder 4.

- Exhaust:- (A)41.033mm - (B)33mm = (Lift)8.033mm

- (A)41.036mm - (B)33mm = 8.036mm

Checking camshaft bearing oil clearance (using plastigauge).

1. Ensure the camshaft journal and bearing are clean.

2. Position a strip of "Plastigauge" on top of the journal (in an axial direction).

3. Place the camshaft caps in position and tighten to specified torque.

4. Remove the camshaft cap and measure the oil clearance.

Oil Clearance:

Journal 1Journal 2Journal 3Journal 4Journal 5Oil clearance0.076

0.0500.0500.0500.076

From the results i determined the cam lobes and bearings were in good enough condition to be used again.

the cam shaft sprockets were visually inspected and were reassembled to within the torque specs.

timing belt was relatively new so was clear for further use

when removing and reassembling the valves,a valve compressor was used.separated the valves from

the springs and measured stems, length and clearance and when passed to within specifications where refitted

onto cylinder head.below is the valve clearance results table

Cylinder 1 | Cylinder 2 | Cylinder 3 | Cylinder 4 | ||||

Position A (i) | 6.47mm | 6.46mm | 6.47mm | 6.47mm | 6.47mm | 6.47mm | 6.47mm |

Position A (ii) At 90° to "A (i)" | 6.42mm | 6.47mm | 6.47mm | 6.47mm | 6.47mm | 6.46mm | 6.47mm |

Position B (I) | 6.47mm | 6.46mm | 6.46mm | 6.47mm | 6.47mm | 6.46mm | 6.47mm |

Position B (ii) At 90° to "B (i)" | 6.42mm | 6.46mm | 6.47mm | 6.46mm | 6.47mm | 6.46mm | 6.47mm |

Position C (i) | 6.34mm | 6.28mm | 6.28mm | 6.32mm | 6.32mm | 6.24mm | 6.33mm |

Position C (ii) At 90° to "C (i)" | 6.41mm | 6.34mm | 6.34mm | 6.02mm | 6.28mm | 6.32mm | 6.29mm |

In | Ex | In | Ex | In | Ex | In | |

Average Reading | 6.42mm | 6.41mm | 6.41mm | 6.36mm | 6.41mm | 6.40mm | 6.41mm |

Cylinder | 1 | 2 | 3 | 4 |

Inlet | Ok | Ok | Ok | Ok |

Exhaust | Ok | Ok | Ok | ok |

OK fail | OK fail | OK fail | OK fail |

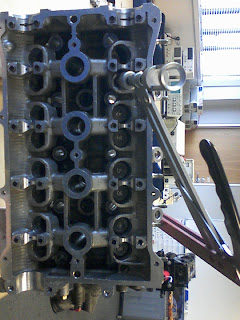

another shot illustrating valves when reassembling the valves and cotters(keepers) which was not an easy task without the specialised tools for it

the tutor provided us wuth torque specification for the Mazda engine which i referenced when reassembling the head components and the head onto the engines short block

Component | Torque specification |

Cylinder head bolts | 76 – 81 Nm |

Water pump | 19 – 26 Nm |

Camshaft caps | 11 – 14 Nm |

Seal plate | 8 – 11 Nm |

Camshaft pulley bolt | 49 – 61 Nm |

Cylinder head cover | 3- 4 Nm |

Timing belt pulley | 108 – 128 Nm |

Idler Puller | 37 – 52 Nm |

Timing belt tensioner | 37 – 52 Nm |

Timing belt cover | 8 – 11 Nm |

Crankshaft pulley | 12 – 17 Nm |

Water Pump Pulley | 8 – 11 Nm |

No comments:

Post a Comment